The Key Factors You Must Consider When Choosing a Precision Casting Foundry

Why It Important to Choose a Reliable Precision Casting Foundry

Choosing a reliable and long-term partner for precision casting can be challenging. The nature of precision castings, which involves the creation of custom molds, makes transitioning a mold to another foundry complex and impractical. Each foundry operates with its own unique materials and shrinkage rates, meaning that once a mold is developed at a specific facility, it cannot simply be shifted elsewhere without complications. This process inherently places significant responsibility on the chosen foundry for the entire production.

Furthermore, clients often have limited opportunities to conduct extensive trials prior to establishing a formal working relationship with a supplier. Consequently, the decision to select a precision casting foundry can be critical. An inadequately skilled supplier or one that lacks effective communication can result in delays in mold development, product quality issues, and disruptions to scheduled timelines.

Therefore, it is essential to carefully consider various factors when selecting the right precision casting foundry from the beginning. We invite you to explore LE-TA 's capabilities to discover how we can serve as the ideal partner for your precision casting needs.

What Must Be Considered When Selecting a Precision Casting Foundry?

When selecting a precision casting foundry, it's critical to consider their expertise with specific metal materials. Working with a foundry that lacks familiarity with your required material can lead to inconsistent quality or even production failures. The most commonly utilized materials in precision casting include:

**Stainless Steel** Grades such as 304 and 316 are recognized for their exceptional corrosion resistance.

**Carbon Steel** This material is often employed in the manufacture of heavy machinery components.

- **Alloy Steel** Known for its high strength and wear resistance, alloy steel is ideal for various demanding applications.

**Copper Alloys** Materials like bronze and brass are valued for their conductive and antimicrobial properties.

**Aluminum Alloys** These alloys are extensively used for lightweight design applications.

For further insights into materials, please refer to our metal analysis guide.

**Technical Capability**

It is essential to ascertain whether the foundry has experience in casting products similar to yours. Each precision casting foundry specializes in particular techniques and handles different grades of materials, which greatly influence the quality of the finished product. To evaluate a supplier's capabilities, you might consider requesting samples of their previous work, allowing for an assessment of their casting standards.

**Casting Quality Control**

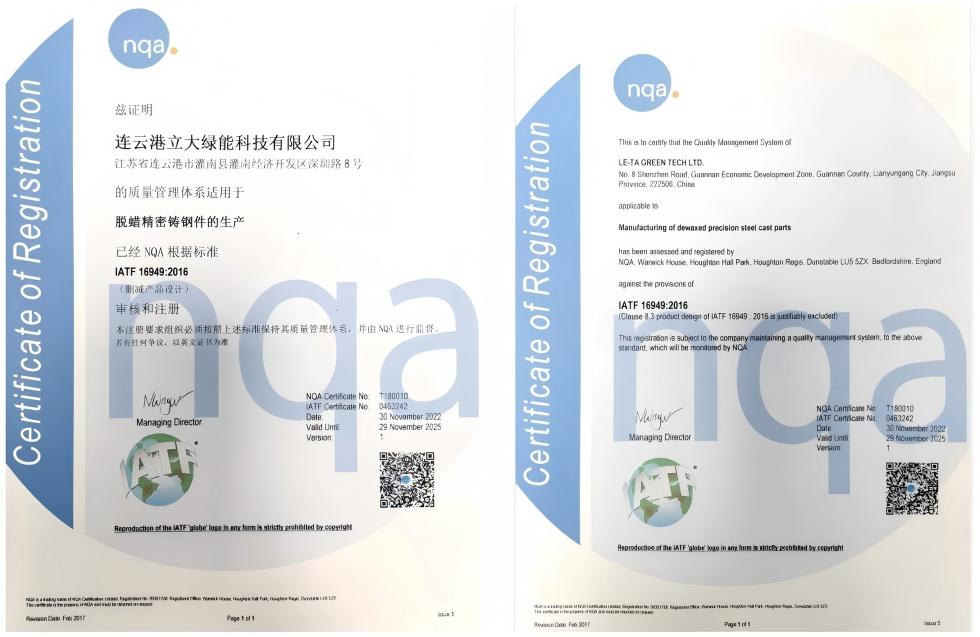

Minimizing product returns is crucial, as they can lead to significant costs. Ensure that the foundry maintains a robust quality inspection process compliant with ISO 9001 standards and IATF 16949. During the initial negotiation phase, ask for documentation, including material certifications, ISO certificates, heat treatment reports, salt spray test results, and tensile test reports. This documentation will help you evaluate the supplier's quality management practices preliminarily. LE-TA is a full certified precision casting foundry with ISO9001, IATF16949, ISO14001, ISO45001 and ISO13485 certifications, to ensure a broader standards conformity as required by different customers from different markets.

**Measurement Capacity**

Do you require nondestructive testing (NDT), mechanical testing, or chemical testing? While all metal casting suppliers can outsource any needed testing, some have all those capabilities in-house, which can potentially save time and money. If your application requires such testing, a casting supplier specializing in high-compliance work with in-house capabilities may be the right fit as well.

**Production Capacity**

Can the foundry satisfy your order requirements and adhere to delivery timelines? Many precision casting foundries have established relationships with existing clients. It is important to clarify their available capacity early in the negotiation process to ensure alignment with your production needs and avoid potential mismatches.

**Machining Capabilities**

Buyers increasingly select casting suppliers who have in-house machining capabilities. This can avoid conflict if defects are discovered during machining. If a third party is machining, it may lead to longer lead times and also result in "finger-pointing" about who is at fault. Is it a casting issue or a machining issue? If the casting supplier discovers an issue during machining, the problem is resolved faster with no dispute over whose fault it is. The foundry "owns it," and there is less time needed for processing, shipping, and handling or replacing. Problem or not, integrated machining simplifies the supply chain and reduces handling time and shipping cost before the product makes it to the customer. LE-TA is equipped with an in-house cutting-edge machining center to meet the higher dimentional requirements of customers to avoid the above mentioned issues from happening.

**Choosing The Right Supplier Value-Added Services**

What do you require from your casting supplier? Are you simply in need of a metal component delivered to your location, or do you have more comprehensive needs? For instance, if your organization lacks in-house metallurgy expertise, it is essential to ensure that the supplier can assist you in selecting the appropriate alloy tailored to your specific application. Additionally, do you seek to enhance your company's overall metallurgical expertise through training or knowledge sharing?

Would you prefer a supplier capable of reviewing your designs and material selections to provide recommendations that could extend the longevity of your products or reduce costs? While some suppliers may excel at manufacturing products to specification, they may offer limited additional capabilities. Others may go above and beyond the terms of the purchase order to help you save time and money.

It is also important to consider whether you require both ferrous and non-ferrous alloys, as certain foundries may have limitations or specializations. Ensuring that the supplier can meet all your material or alloy requirements can help mitigate the need for multiple vendors.

**Tour Their Facility**

One of the best ways to assess a potential casting supplier is by experiencing their operations firsthand through a plant tour. Most manufacturers will welcome you as a guest in order to earn your business. If you leave the tour with any reservations about their operations, capabilities, or company culture, this may indicate that they are not the right fit for your needs.

Questions to Consider:

- Does the supplier have experience with your specific products and/or markets?

- Can the supplier fulfill multiple product requirements to reduce the necessity for various vendors?

- What factors are most important to you? Is it quality, price, customer service, or something else? How do the supplier's strengths align with your needs?

- Does the supplier possess the necessary certifications?

- Are they equipped with proper testing capabilities?

- Do they have regular experience with the required alloys?

- What value-added services are important to you, and does the supplier provide them?

- Is the company stable, with a solid history and promising future?

- Do their values align with yours?

- Can you envision a long-term business relationship with them?

- What types of casting products does the supplier offer?

**Communication Efficiency**

Assess the supplier's responsiveness and professionalism in addressing your needs. The speed at which they provide quotations and the promptness of their sales or R&D teams in replying to emails are indicative of their proactiveness. If delays occur at this stage, it may be worth exploring alternative suppliers to ensure quality service.

**Casting Supplier Geographic Location**

Geographical proximity can significantly influence overall costs and delivery schedules. When choosing a foundry, take transportation and logistics into account. Selecting a nearby precision casting facility can lead to reduced shipping costs and shorter delivery times. For international procurement, also be mindful of import duties, anti-dumping penalties, CBMA taxes, and other relevant trade considerations.

Conclusion

While some might approach metal castings as mere commodities, the reality is that they deserve a more thoughtful selection process tailored to your specific needs. Conduct an internal audit of your company's requirements and priorities to identify what is most crucial. Investigate the supplier's website, engage with a sales representative or business associate, and ask comprehensive questions. Visiting their facility will provide insight into their capabilities and help you determine if you can establish a strong, mutually beneficial relationship.

China's Leading Stainless Steel Precision Casting Foundry

LE-TA Precision Casting is a wax-based foundry located in Jiangsu, China, specializing in stainless steel precision casting. It delivers high-volume, consistently high-quality castings to industries such as door hardware, auto parts, petrochemicals, medical equipment, marine, hand tools, and food equipment etc. With an impressive 95% above self-production rate, LE-TA' s production line encompasses mold design, fluid analysis, wax model creation, shell making, dewaxing, metal pouring, post-processing (e.g., acid pickling, alkaline treatment), sandblasting, heat treatment, machining, assembly, and packaging. Its stainless steel production line supports materials such as 304 (CF8), 316 (CF8M), and 17-4 stainless steel. Currently, there is available production capacity—feel free to request a quote!